A Vehicle Restraint is a vital safety device used at loading docks to secure trucks and trailers during

loading and unloading operations. As logistics operations become faster and more complex, the risk of dock-related

accidents continues to rise. This article provides an in-depth explanation of what a vehicle restraint is, how it works,

why it is essential for dock safety, and how businesses can choose the right system to improve efficiency and comply with

safety standards. Drawing on real-world applications and industry best practices, this guide is designed to help

warehouse managers, safety officers, and logistics professionals make informed decisions.

What Is a Vehicle Restraint?

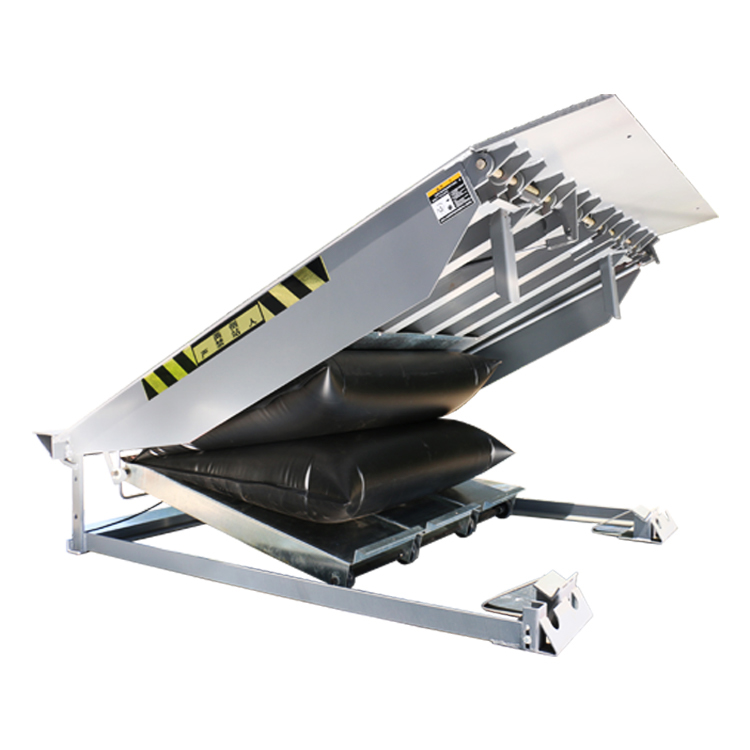

A Vehicle Restraint is a mechanical or hydraulic safety device installed at a loading dock to prevent

trailers and trucks from moving away from the dock during loading and unloading. By securing the rear impact guard

(RIG) or wheels of a vehicle, the restraint minimizes the risk of premature departure, trailer creep, or accidental

roll-away.

Unlike traditional wheel chocks, which rely heavily on human intervention and correct placement, a vehicle restraint

system provides a more reliable and standardized solution. Many modern facilities rely on automatic vehicle restraint

systems to maintain consistent safety protocols.

According to industry data, dock-related accidents account for a significant percentage of warehouse injuries. A

properly installed vehicle restraint acts as the first line of defense against these incidents.

Why Is a Vehicle Restraint Critical for Loading Dock Safety?

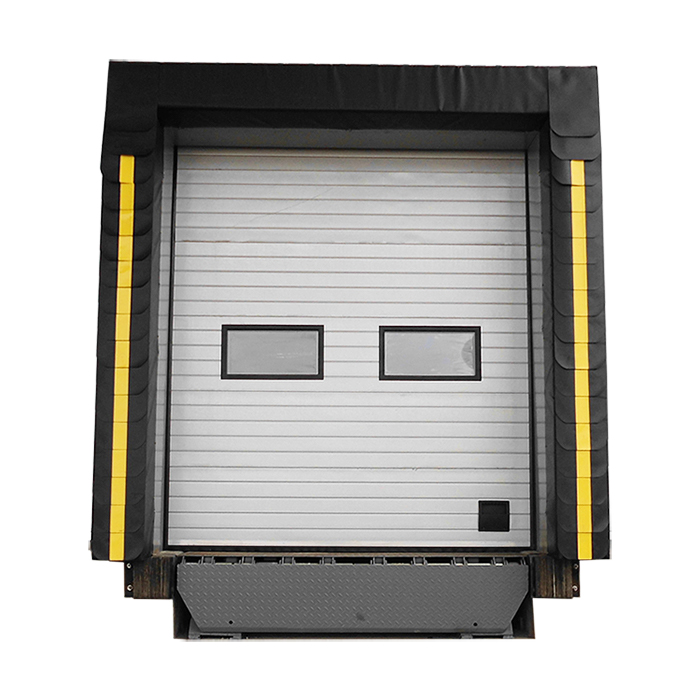

Loading docks are among the most dangerous areas in any warehouse or distribution center. A vehicle restraint plays

a critical role in protecting workers, goods, and equipment by eliminating unexpected vehicle movement.

-

Prevents early truck departure during loading

-

Reduces the risk of forklift fall-through accidents

-

Improves compliance with OSHA and warehouse safety standards

-

Enhances overall operational confidence for dock workers

Companies such as Yueruis emphasize dock safety solutions that integrate seamlessly with modern

logistics workflows, helping facilities achieve both safety and productivity goals.

How Does a Vehicle Restraint Work?

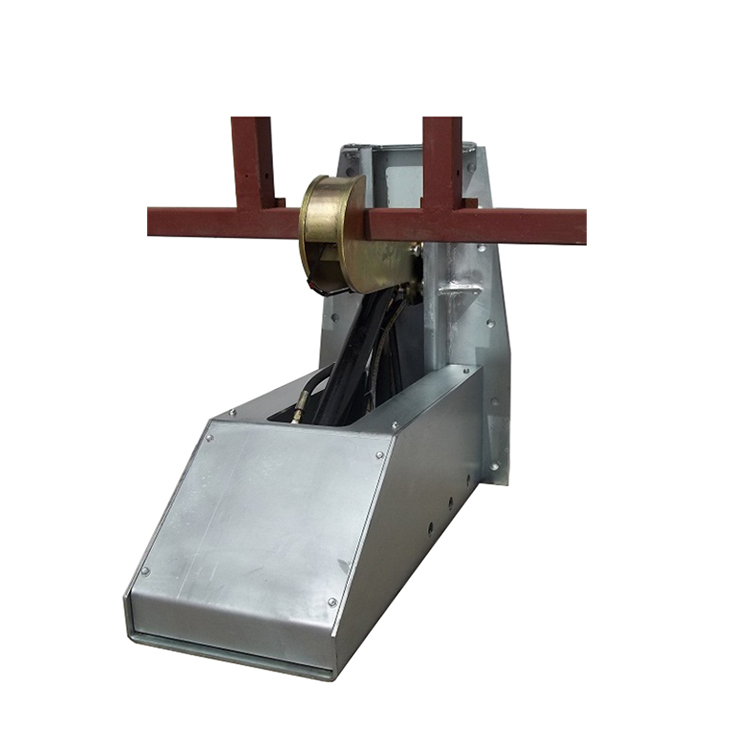

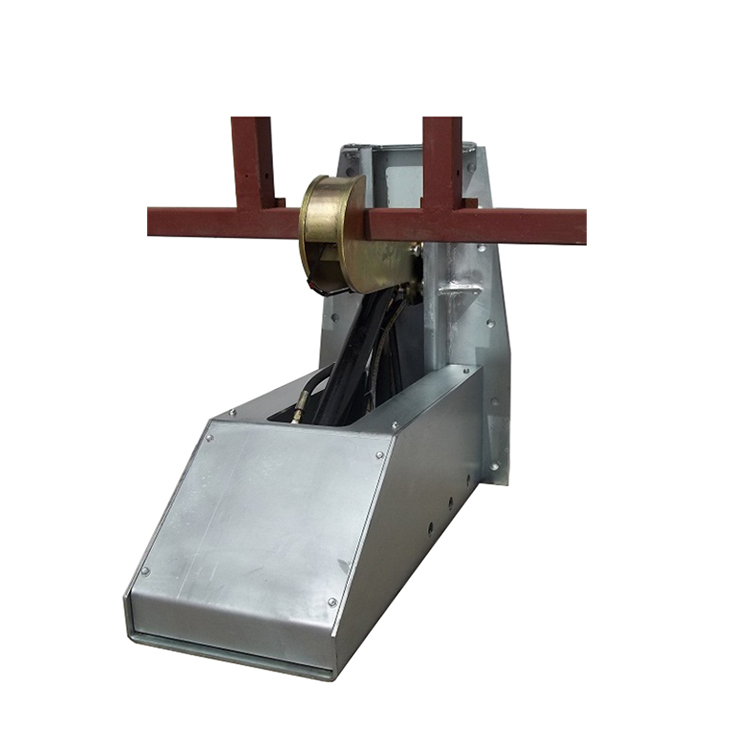

A vehicle restraint system typically engages the rear impact guard of a truck once it is properly docked. The system

is activated either manually or automatically, depending on the design.

-

The truck backs into the loading dock.

-

The restraint automatically or manually locks onto the rear impact guard.

-

Signal lights indicate a safe loading condition.

-

Loading and unloading operations begin.

-

The restraint is released only after dock operations are complete.

For a detailed overview of common configurations, you may refer to this vehicle restraint system resource.

Types of Vehicle Restraint Systems

Different facilities require different types of vehicle restraints based on traffic volume, dock layout, and trailer

compatibility.

|

Type

|

Description

|

Best Use Case

|

|

Mechanical Vehicle Restraint

|

Manually operated locking mechanism

|

Low to medium traffic docks

|

|

Hydraulic Vehicle Restraint

|

Powered system with automatic engagement

|

High-volume logistics centers

|

|

Wheel-Based Restraint

|

Secures wheels instead of RIG

|

Specialty trailers or older fleets

|

Vehicle Restraint vs. Wheel Chocks

While wheel chocks have been used for decades, they are increasingly viewed as insufficient for modern safety

requirements.

-

Vehicle restraints provide visual confirmation of engagement.

-

Wheel chocks rely on correct placement by operators.

-

Restraints integrate with dock levelers and doors.

-

Chocks are prone to misuse and human error.

Key Benefits of Installing a Vehicle Restraint

Installing a vehicle restraint system delivers both immediate and long-term advantages.

-

Enhanced worker safety

-

Reduced cargo damage

-

Improved loading efficiency

-

Lower insurance and liability risks

How to Choose the Right Vehicle Restraint

Selecting the right vehicle restraint depends on several operational factors:

-

Dock traffic volume

-

Trailer types and compatibility

-

Automation requirements

-

Local safety regulations

Consulting experienced manufacturers like Yueruis can help ensure the system fits your specific dock

environment.

Maintenance and Compliance Considerations

Regular inspection and maintenance are essential to keep vehicle restraint systems functioning properly. Preventive

maintenance not only extends equipment life but also ensures ongoing compliance with safety standards.

-

Monthly visual inspections

-

Annual professional servicing

-

Employee training on proper usage

Frequently Asked Questions (FAQ)

Is a vehicle restraint mandatory?

While regulations vary by region, many safety authorities strongly recommend vehicle restraints as best practice for

dock safety.

Can vehicle restraints work with all trailers?

Most modern vehicle restraints are designed to accommodate standard rear impact guards, but special trailers may

require customized solutions.

How long does installation take?

Installation typically takes one to two days, depending on dock conditions and system complexity.

Final Thoughts

A vehicle restraint is not just an accessory—it is a critical safety investment for any facility with loading dock

operations. By reducing accidents, improving efficiency, and ensuring compliance, vehicle restraint systems play a

key role in modern logistics safety strategies.

If you are planning to upgrade your loading dock safety or need expert guidance on choosing the right system, contact us today. The team at Yueruis is ready to help you build a safer and more

efficient loading dock solution.