A vehicle restraint system is one of the most critical safety solutions used in modern loading dock operations. It prevents unintended vehicle movement during loading and unloading, significantly reducing the risk of accidents, injuries, and product damage. In this in-depth guide, we explore what a vehicle restraint is, how it works, its main types, safety benefits, compliance standards, and how choosing the right system can dramatically improve dock efficiency and safety.

A vehicle restraint system is a dock safety device designed to secure trucks, trailers, or vehicles in place during loading and unloading operations. Its primary function is to prevent trailer creep, premature departure, or unintended vehicle movement that could create dangerous gaps between the dock and the vehicle.

Unlike traditional wheel chocks, vehicle restraints provide a more reliable and operator-independent solution. They physically engage the rear impact guard (RIG) of a trailer or lock the vehicle at the dock, creating a controlled and secure loading environment.

According to industry data, vehicle movement accidents account for a significant percentage of loading dock injuries. This is why more warehouses, logistics centers, and distribution hubs are replacing wheel chocks with advanced vehicle restraint systems.

Trailer creep occurs when a trailer slowly moves away from the dock due to forklift traffic entering and exiting. Even a few inches of movement can cause dock leveler failure or forklift tip-over accidents. A vehicle restraint eliminates this risk by physically holding the trailer in position.

Wheel chocks rely heavily on human behavior. If an operator forgets to place or remove them properly, safety is compromised. Vehicle restraints use interlocked control systems, lights, and alarms to ensure correct engagement before loading begins.

Modern vehicle restraint systems integrate with dock levelers, doors, and signal lights. This coordinated safety sequence ensures that loading only occurs when the vehicle is fully secured.

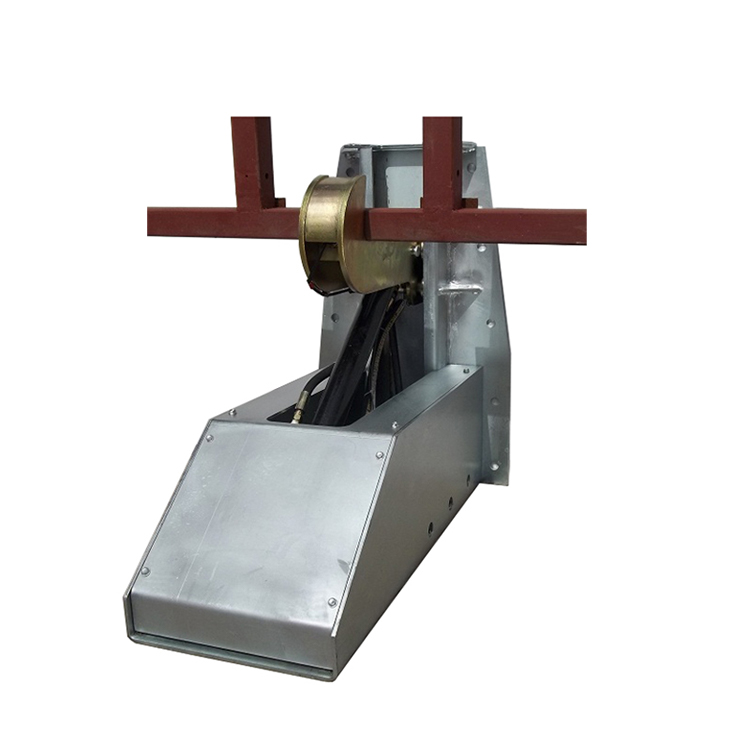

A vehicle restraint system operates through a combination of mechanical or hydraulic components and visual communication signals. Here is a simplified operating sequence:

This controlled workflow significantly reduces premature truck departure, which is one of the most dangerous dock-related incidents.

| Type | Description | Best Use Case |

|---|---|---|

| Hook-Style Vehicle Restraint | Engages the trailer’s rear impact guard using a rotating hook | Standard trailers and high-volume docks |

| Wheel-Based Restraint | Secures the rear wheel instead of the RIG | Trailers with damaged or inconsistent RIGs |

| Manual Vehicle Restraint | Operated without hydraulics | Low-frequency dock operations |

| Hydraulic Vehicle Restraint | Fully automated with advanced safety interlocks | Busy distribution centers |

Companies like Yueruis focus on engineering vehicle restraint solutions that combine durability, reliability, and intelligent safety design to meet modern logistics demands.

| Feature | Mechanical | Hydraulic |

|---|---|---|

| Automation Level | Low | High |

| Maintenance | Minimal | Moderate |

| Safety Integration | Limited | Advanced interlock systems |

While OSHA does not mandate a specific type of vehicle restraint, it strongly emphasizes preventing unintended vehicle movement. Many safety audits and insurance providers now recommend vehicle restraint systems as a best practice for dock safety compliance.

Installing certified vehicle restraints demonstrates a company’s commitment to employee safety and operational excellence.

Working with an experienced manufacturer like Yueruis ensures the selected vehicle restraint matches both operational needs and long-term safety goals.

Yes. Vehicle restraints provide active, physical engagement and visual communication, making them far more reliable than wheel chocks.

Most modern systems are designed to accommodate a wide range of trailer designs, including those with varying rear impact guards.

High-quality vehicle restraints are built for heavy-duty use and require only routine inspections and basic maintenance.

A vehicle restraint system is no longer an optional accessory—it is a fundamental component of safe and efficient loading dock operations. By preventing vehicle movement, improving communication, and integrating with dock equipment, vehicle restraints significantly reduce risk while enhancing productivity.

If you are planning to upgrade your loading dock safety or looking for a reliable vehicle restraint solution, Yueruis offers professional-grade systems designed for real-world logistics challenges. Contact us today to discuss how we can help improve your dock safety and operational efficiency.