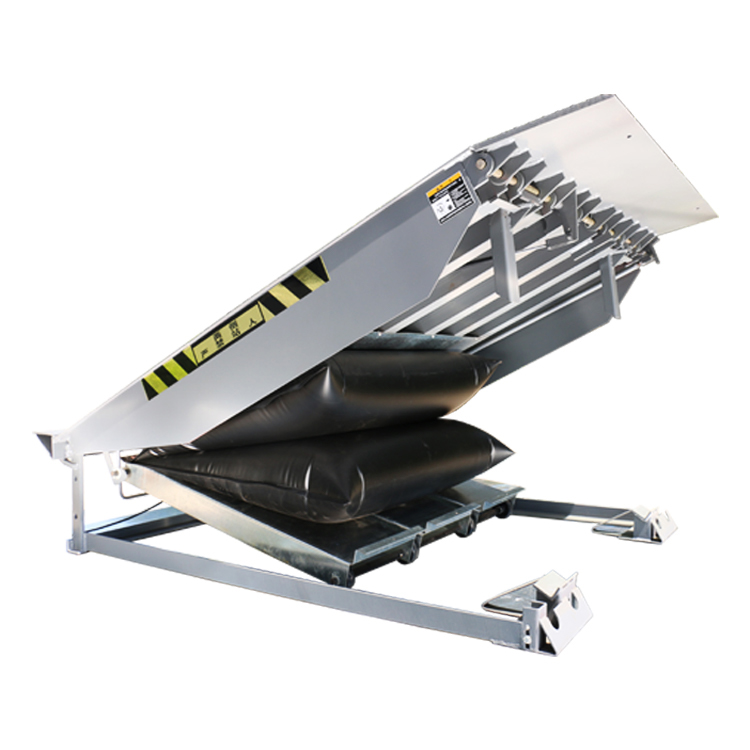

Factory cargo dock levelers are an important part of the entire facility process of an enterprise. The dock leveler is the starting point and end point of the material flow process in the facility. The platform is a bridge design used to connect the cargo platform and the gap at the rear of the truck during loading and unloading operations. Different working occasions require different dock levelers. The cargo dock levelers mainly consists of three parts: base, load plate and power system.

Dock levelers are divided into fixed dock levelers and mobile dock levelers. Its main function is to build a bridge between the cargo platform and the transport vehicle, so that the forklift can travel conveniently to achieve the purpose of loading and unloading.

Mobile dock leveler: widely used in cargo platforms without loading and unloading equipment and mobile loading and unloading places. It is a cargo loading and unloading auxiliary equipment used in conjunction with forklifts. With the help of the boarding bridge equipment, the forklift can directly drive into the car compartment for batch loading and unloading operations. The biggest feature of the mobile dock leveler is that it is easy to move and is used in wider places, not suitable for places with smaller sites.

Fixed dock leveler: It is a special auxiliary equipment for fast loading and unloading of goods. Its height adjustment function builds a bridge between the truck and the cargo platform in the warehouse. Forklifts and other handling vehicles can directly enter the truck to load and unload goods in batches. Fixed dock leveler can be used in places with smaller sites.