In modern logistics loading and unloading scenarios, the vehicle restraint system is a key device to prevent vehicles from moving unexpectedly and ensure the safety of personnel and goods. Standardizing the operation process is a necessary condition for giving full play to the protective function of the equipment and achieving safe and efficient operations. It is of great significance for reducing logistics risks and improving operation efficiency.

Pre-operation inspection is the foundation of safe operation. A comprehensive performance check of the vehicle restraint system is required: inspect whether there is any deformation or crack in the mechanical parts to avoid structural damage affecting the restraint effect; check whether the hydraulic or electrical system pipelines are firmly connected and undamaged to prevent power transmission faults from causing restraint failure; confirm that the control device buttons and indicator lights are functioning properly to ensure accurate feedback of operation information. At the same time, check the vehicle parking status to ensure that the vehicle is aligned with the loading and unloading platform, the tires are within the effective range of the restraint system, and there are no obstacles in the operation area.

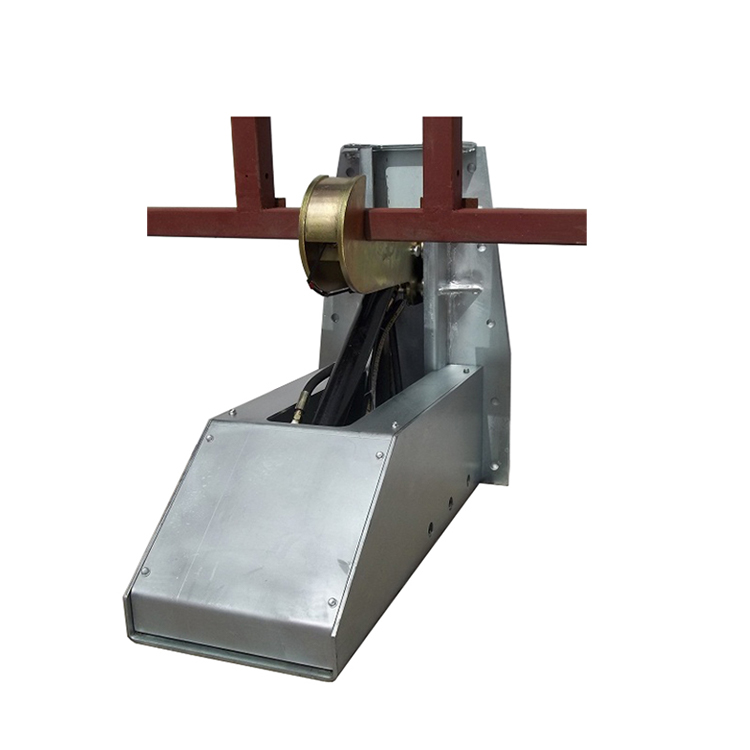

The operation process directly affects the restraint effect. Before starting the equipment, the operator needs to issue a safety warning through the control device. According to the vehicle type and tire size, select the appropriate restraint mode. For mechanical lock type, ensure that the lock hook accurately hooks the tire or the fixed point of the chassis; for hydraulic type, observe whether the pressure value reaches the rated standard; for electric type, confirm that the display screen shows that the locking is completed. During the operation, continuously monitor the equipment operation. If there is any abnormal sound, vibration or incomplete restraint, stop the machine immediately to check for faults.

The handling of the equipment after the loading and unloading operation is also crucial. Before releasing the restraint, confirm that the operation is completed and personnel have evacuated to a safe area. Release the restraint smoothly through the control device to avoid impact force damaging the vehicle or equipment. After release, clean the equipment in time to remove dirt, oil stains and other debris, check the wear of components, and replace damaged parts in time. Regularly perform lubrication and maintenance, replenish hydraulic oil for the hydraulic system, and test the insulation of the electrical system's circuits. Keep a record of equipment operation to provide data support for maintenance and repair.

The reliable operation of the vehicle restraint system depends on strict operation and systematic maintenance. Strictly following the operation specifications can not only build a solid safety line for loading and unloading operations but also extend the service life of the equipment, providing a solid guarantee for the efficient operation of modern logistics.